Ripped Products

Ripped Lumber Manufacturing Machines

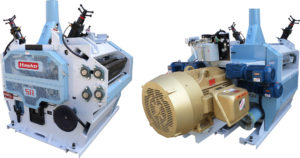

HASKO’s experience in rough mill operations provides special insight into complex ripping and cut-to-length projects. Innovative technologies such as rip optimization increase lumber yield while reliable, high-speed automated feeding systems save labor and increase throughput. HASKO Gang Rip Saws, which have feed capacity ranging from 24 to 36 inches, are legendary throughout the industry for consistent performance in ripping hardwood lumber.

Our experts can help you avoid bottlenecks in production and improve rip yield while decreasing labor expenses. Hardwood lumber costs account for up to 70 percent of the total product costs of secondary wood-products producers in the United States. Reducing these costs is difficult and requires an investment in technology.1

According to U.S. Forest Service calculations, production of wooden products other than pallets (i.e., appearance-grade lumber) in the United States annually consumes approximately 5.3 billion board feet of hardwood lumber. Experts estimate that, on an individual manufacturing-location level, a 1 to 2 percent yield increase in an average rough mill saves from $150,000 to $300,000 annually.2

HASKO can help ripped lumber manufacturers attain a stronger operational efficiency evolution by studying their input and output and calculating the benefits of improvements to the process.

Source 1- http://www.nrs.fs.fed.us/pubs/gtr/gtr-p-78papers/10buehlmannp78.pdf

Source 2- http://www.nrs.fs.fed.us/pubs/gtr/gtr-p-78papers/10buehlmannp78.pdf