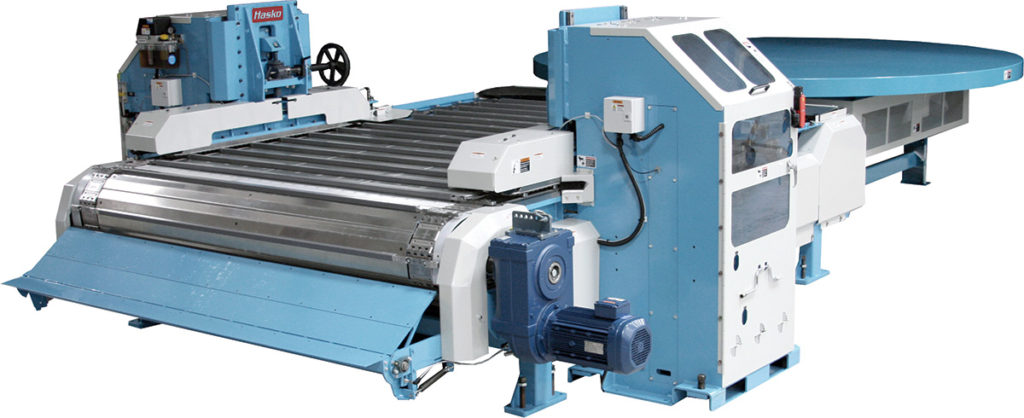

PF MPEM-RW (Rework)

Pre-finishing lines require some rework and repairs after the factory finish has been applied. The Hasko PF-MPEM is the latest HASKO Rework end matcher series. The machine is configured on a common frame that allows for one operator to select either end to be end matched without recutting a good end. The optional configuration is to have two operators that would do all defect cutting and selections. The system is very compact and lends itself to a variety of infeed and exit options. They are equipped with non-marking hold-downs and normally are purchased with extra space on each unit for end dressing or touch up stations for the finished flooring that has be re-cut. These machines can be used for both solid and engineered wood.

The Hasko Advantage End Matcher Buyer’s List

Application

Pre-finishing lines require some rework and repairs after the factory finish has been applied. The PF MPEM RW can be used for both solid and engineered wood.

Features

- An optional configuration allows two operators to perform all defect cutting and selections

- Its very compact design lends itself to a variety of in-feed and exit options

- Equipped with non-marking hold-downs

- Normally are purchased with extra space on each unit for end-dressing or touchup of finished flooring that has be re-cut

Specifications

- Shaft Centers: 12′-8″

- Overall Length: 14′

- Loading Space: 2′

- Closed Stations

- Even End Rolls: 24″

- Exit Out: End Exit

- Feed Drive HP: 10

- Max. Lugs Per Min: 100

“…your End Matcher chain has never had a problem at all…while chain on the other machine requires regular maintenance and replacement.”