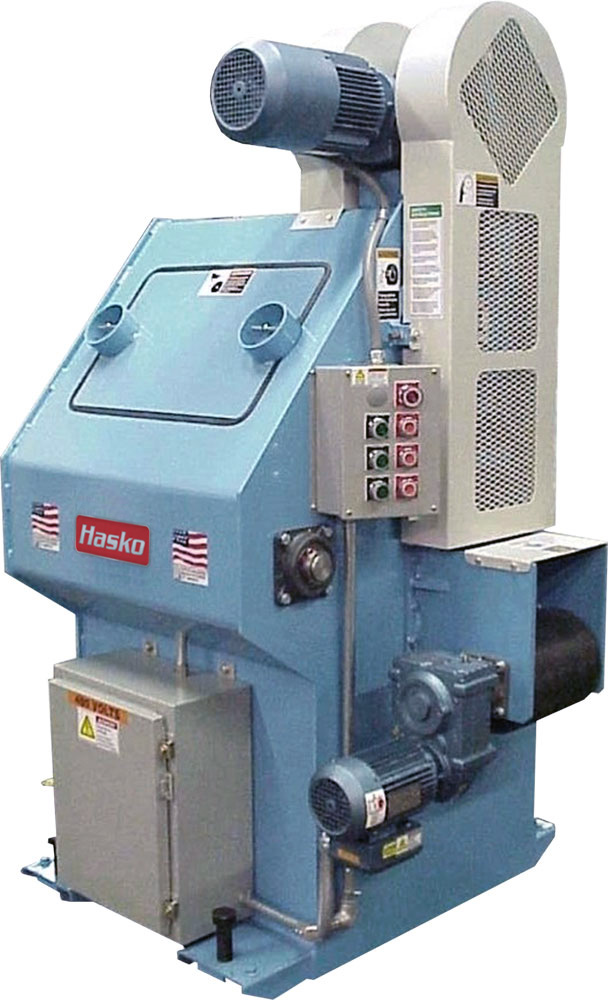

HSSS Strip and Scrap Saws

Automatic In-Line Strip and Scrap Chopper

The HASKO HSSS cuts scrap-handling down to size for a simple, economical solution to an age-old problem. This machine reduces long edgings, shims, and other rippings into a manageable size to eliminate labor and a variety of handling problems.

Application

Developed for fully automatic in-line strip and scrap chopper, the HASKO HSSS reduces rippings, edgings and other long scrap.

Features

- Uses less horsepower than a hog- or scrap-grinder

- Overall dimensions: 45″ wide x 47″ deep x 80″ high

- Approximate weight: 1,500 lbs

- Minimal increase in plant decibel level, with no banging or pounding like in “home-built” units

- Bottom-free falling discharge prevents jamming or material bridging

- Simple and effective clamp-and-cut mechanism

- Maintenance-friendly design

- HASKO-tough for years of endurance

- Built-in controls, access panels and dust chute

- Makes 45 automatic cuts per minute

- Compact design

Specifications

Capacities

- Maximum thickness up to 4”

- Maximum width up to 8”

- Maximum length of infeed material – endless

- Chopped length adustable by conveyor speed and belt traction ~ 16” standard

- Cuts per minute: 45/min preset (cam actuation)

- Feed rate: 60-70 FPM

- Weight: 1,750 pounds

- Floor Space: 54” wide x 50” deep x 84” high

Horsepower & Electrical

- Saw Arbor: 10 HP

- Stroke: 2 HP to double shaft gear box

- Infeed Roll: 1 HP gear box (belt conveyor optional)

- Panel: NEMA standards, mounted

- Controls: 110 volt start/stop

Feed System

- Bottom infeed roll: 8” diameter, lagged

- Roll drive: 1 HP gear box

- Feed rate: 60-70 FPM standard (preset to customer specs)

- Clamping: 7 spring-loaded plungers

General Specifications

- Arbor size: 1 1/4” threaded, double bearing

- Saw size: 16”

- Infeed opening: 8” w x 6” h

- Bedline height: 28” (standard)

- Discharge opening: 14 1/4” x 28” (bottom standard)

- Rear discharge (optional)

- Dust chute: 8” top, via internal baffles

Videos

Coming soon.