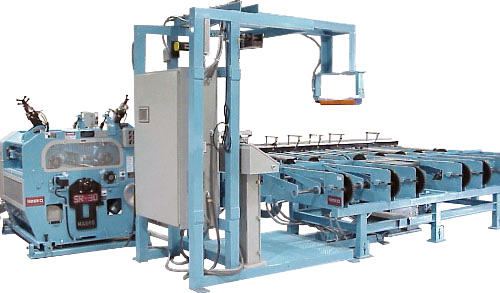

HSLS Rip Optimization

Rip Optimizing Scanning System

The HSLS Rip Optimization System is one of the most simple yet accurate optimizing systems in the industry. It is designed to increase board yield while decreasing labor costs.

Application

The HASKO HSLS is a simple yet robust, cost-effective, rip-to-width solution that can improve overall yield and lumber utilization while optimizing production. It is ideal for flooring, moulding, dimension, and other straight-line, rip-to-size operations for high-production, fixed-arbor, straight-line, rip-to-width optimization.

Features

- Laser scanning system uses two scanning positions to determine board width and side bow

- Available as a complete system or as a separate scanner/shifting in-feed table/gang ripsaw that can be integrated with other rip systems

- Simple and robust HASKAN Laser Light Curtain and software matches saw spacing on fixed-arbor ripsaws

- Integrated bow busting saw and clamp for excessive side bend

- Boards are scanned for width and geometry and best rip solutions are determined

- Information transmitted to the HASKO HSRF shifting guide ripsaw feeder automatically positions the board into the HASKO SR-Series straight-line gang ripsaw

- User-friendly software for easy programming of unlimited arbor definitions

- Touch-screen panel provides quick changeovers and data entry

- Manual mode and/or solution override and bow-busting are controlled through the operator joystick

- Customer parameters for daily, gross, targeted widths, board count, and arbor pocket tallies are pre-programmed into the software prior to shipping

- Busted boards remain in the system; the rip feeder manages cut boards into the saw when the fixed saw system is in use

Specifications

- Hasko offers multiple board rip optimizing solutions. We have multiple automated features that enhance your board yield while reducing labor and improving safety.

- Hasko offers both Fixed saw ripping on the Hasko SR-Series Gang Ripsaws. The Hasko SRMA with patent pending saw shifting technology for up to 5 moving saws.

- The Hasko HSLS Board scanning system uses one scanning position to determine the board width and side bow. Optional automatic board flipping and automatic side bow busting is available with cupped board detection. The automatic bow busting will only cut boards when the cut will improve the board rip combinations.

- The busted boards remain in the system and the Hasko HSRF rip feeder will manage the cut boards into the saw when the fixed saw system is used. The Hasko SSGF is used when the Shifting saw system is utilized.

- We offer turn- key systems from the package deck to the rip sorting system or we can design our machinery into your existing lumber delivery system. Whatever your needs are, let us demonstrate what Hasko can do for you.