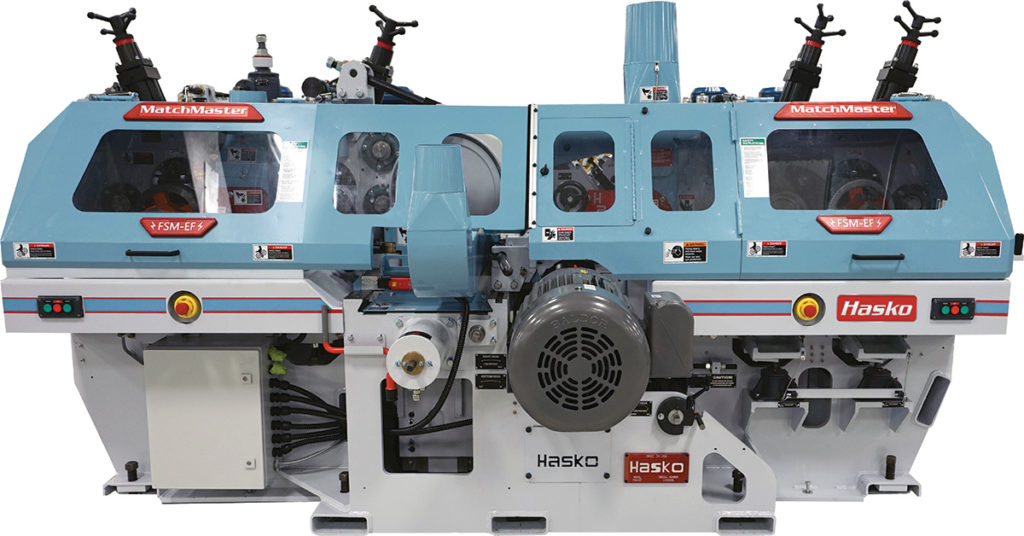

FSM MatchMaster

Flooring Side Matcher

Commonly referred to as “The King of Flooring Machines,” the HASKO FSM MatchMaster leads the industry in production, runtime efficiency and maintained accuracy. As factory prefinished flooring changed the wood flooring industry, their required tolerances have driven HASKO to be the manufacturer’s side-matcher of choice.

Application

HASKO offers complete solutions for your Solid Wood and Engineered Wood Flooring manufacturing needs.

-

- For strip and plank flooring side matching tongue and groove

-

- Hardwood, softwood and exotics

-

- Ideal for high-speed S4S applications up to 7” wide

- Eased edge and other similar side profiles

Features

- State-of-the-art safety features include door interlocks and zero speed sensing, safety circuitry

- HASKO “Quick Clear” function provides repeat set up for top head and left side head within .002″

- All cutterheads and feed drives are inverter controlled and include braking

- All top feed rolls and centermatch rollers are raised pneumatically and reposition to exact setup when closed

Options

- High-speed side head motors available for speeds up to 6,000 RPM

- Oil mist lube system for top head, bottom head, and hollow back units for up to 4,800 RPM speeds

- Feed speeds up to 600’/min

- Higher horse power cutterheads for higher speeds as required

- Top and bottom cutterheads with up to 16 knives

Specifications

Many new features have been added or improved as ongoing product development and continuous improvement:

- Shortest material: 10″

- Standard material width: up to 6″ face, or 6.5″ rough

- Capacity: 2″ x 6″ or 2″ x 10” optional

- Top head: up to 75 HP

- Bottom head: up to 50 HP

- Side heads: standard left side 30 HP and right side 25 HP

- Hollow back: standard 20 HP

- Cutterhead speeds: 3600 rpm – 6000 rpm

- Feed drive: 150ft/Min up to 600ft/min. optional

Photos

Videos

FSM Electric Feed Retrofit Upgrade

Hasko is committed to continuous improvement through technological advances. Add our new FSM electric feed upgrade to your existing machine to improve performance while significantly reducing operating costs.

See How the FSM Electric Feed Retrofit Pays for Itself!

Cost Reduction Benefits

- New 40 HP combined electric drive reduces energy costs and preventive maintenance, compared to existing 75-100 HP hydraulic drives.

- Projected 2% annual increase of efficiency and run time, increasing throughput.

Retrofit Upgrade Benefits

- Machine runs cleaner and quieter

- Easier to maintain and operate

- Dependability enhanced since the system is not dependent on a single pump or motor

- Consistently higher torque and improved operating efficiency at high and low feed rates

- Better face work due to improved speed control

- Locking and shifting system powered by efficient, vane pump with electric motor

This Package Includes

- Eight 5 HP inverter-controlled, electrically-driven gear reduction units

- Eight complete shaft drive assemblies with bearings and telescoping universal joints

- Heavy-duty mounting framework and safety guards

- Revised electrical schematic program documentation and replacement parts list

“We recently installed an electric feed upgrade FSM Side Matcher & Feed table. The owner Wesley Weaver (Oakcrest Lumber) called to report that they are now producing 3000-3200 more square feet per shift at the same feed rate due to more consistent flow with less hang-ups and jams. This adds up to significantly more sales dollars per shift, not to mention reduced maintenance and hydraulic cost and energy savings. In some installations, payback can be attained in as little as 6 months.”