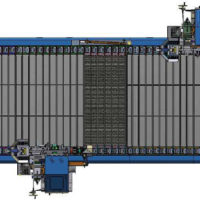

MPEM-C EndMatcher

For Solid and Engineering Flooring

The new HASKO MPEM-C models offer the best new features available for end-matching random-length solid and engineered wood. Its clean, heavy-built design provides multiple benefits.

View Brochure The Hasko Advantage End Matcher Buyer’s List

Applications

- PF Series for pre-finished engineered flooring

- MPEM-RW and PFSW Series for pre-finished solid wood rework systems

- TF Series for truck flooring

- Locking profiles and other special applications

Features

- HASKO independent chain system provides unsurpased accuracy

- Saw stations have “on-the-fly” machine tool quality adjustments

- Dust enclosure improves dust collection and eliminates internal dust hoods

- Single-piece chain bed liners provide long life and low maintenance

- Available with open trim stations for inline defecting or closed stations without operators

- Additional Spindles Optional

- Automatic lug loading and lug unloading available

- Custom machine configurations available

- Many options available for pre-finished flooring and engineered wood

Specifications

- Longest material: 8′ finished length (longer capacity is optional)

- Shortest material: finished 8 1/2″

- Spindles: standard 5 HP all inverter controlled (higher HP is optional)

- Thickness: 5/16″ – 2″

- Max. width: 7” on closed model and 12” on open model

- Standard spindle speeds: optional up to 6000 RPM

- Feed drive: 10 – 20 HP based on speed and length

- Feed speeds: up to 200 lugs per minute

- Feed chains: heavy-duty 6″ pitch feed chains

- Lug spacing: 3” to 12”

- Tooling: standard 10″ diameter and 12″ diameter on open trim stations

Photos

Videos

“…your End Matcher chain has never had a problem at all…while chain on the other machine requires regular maintenance and replacement.”